EGR

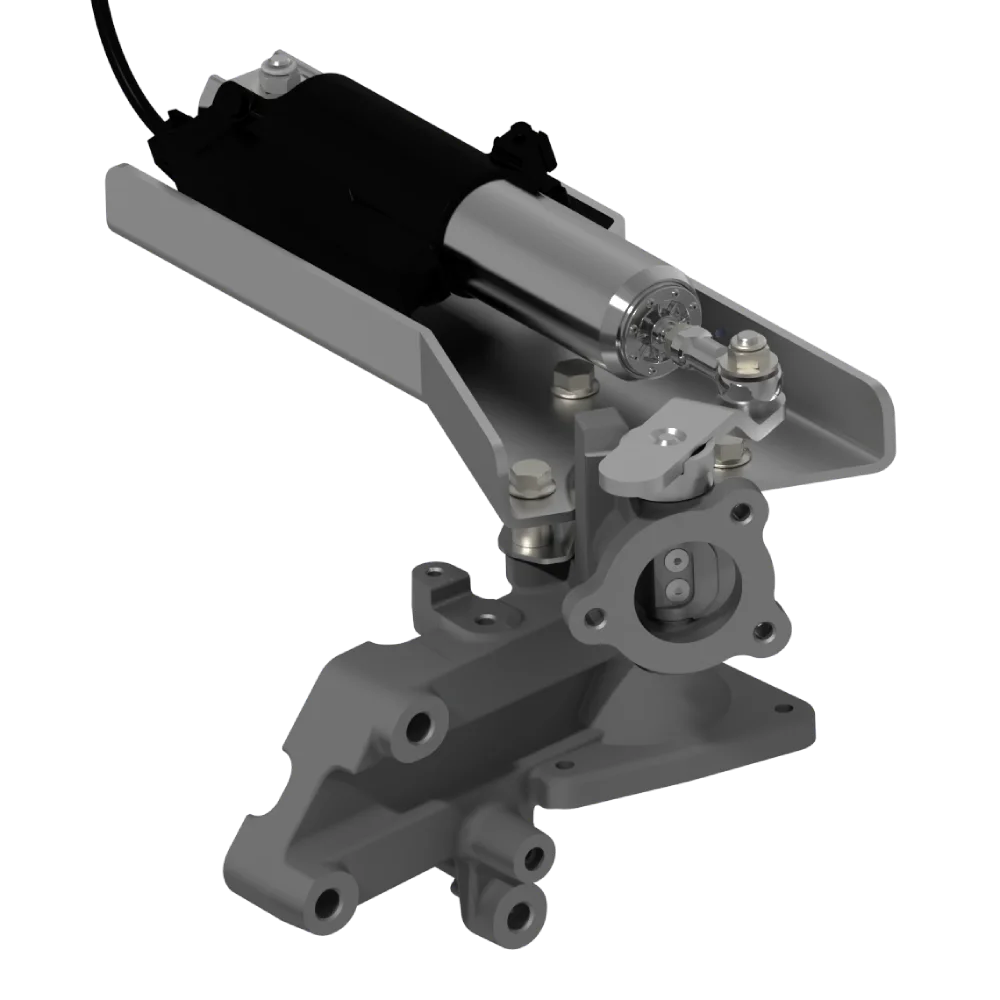

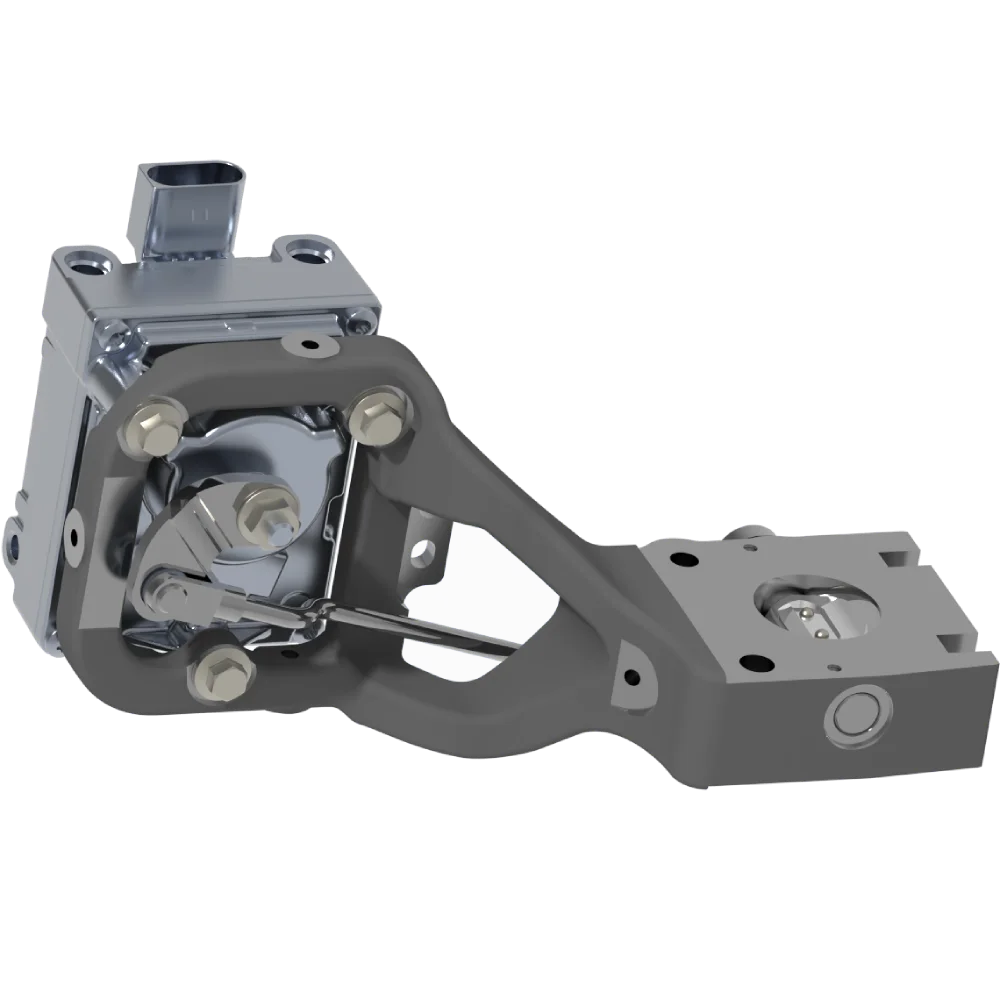

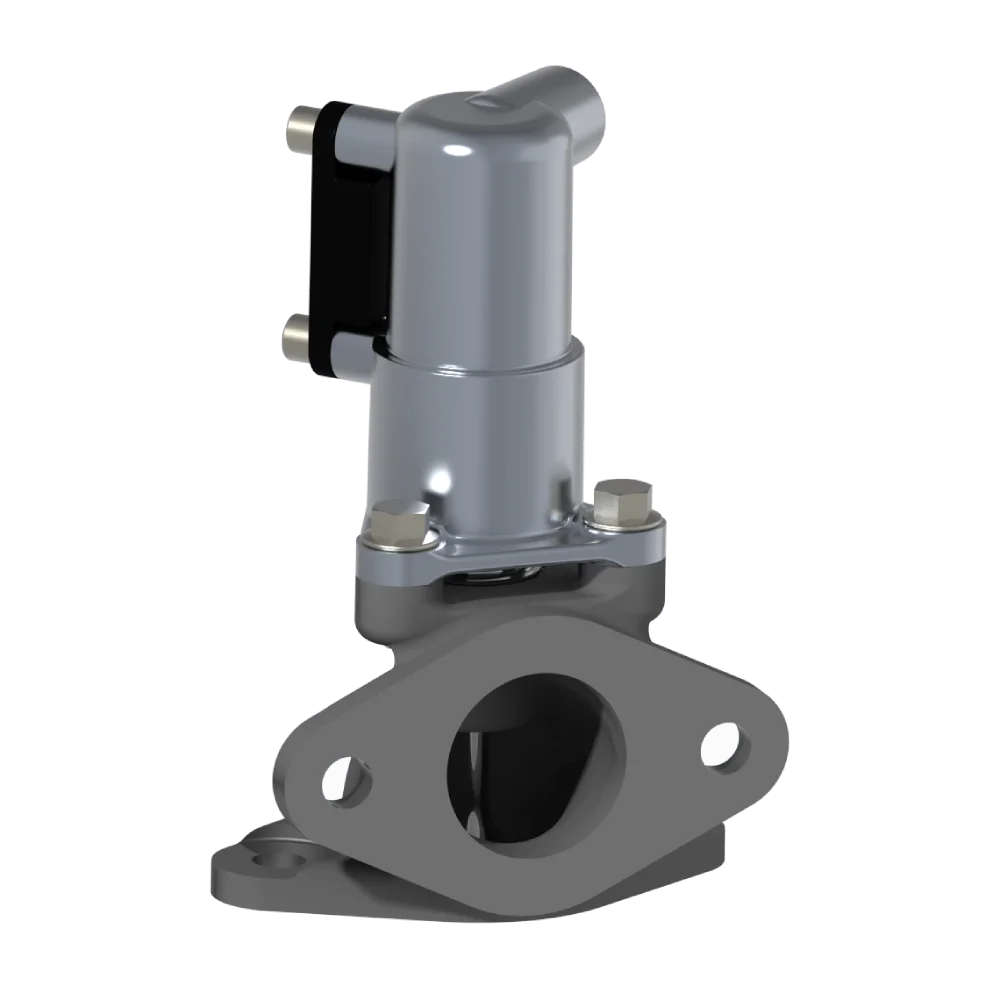

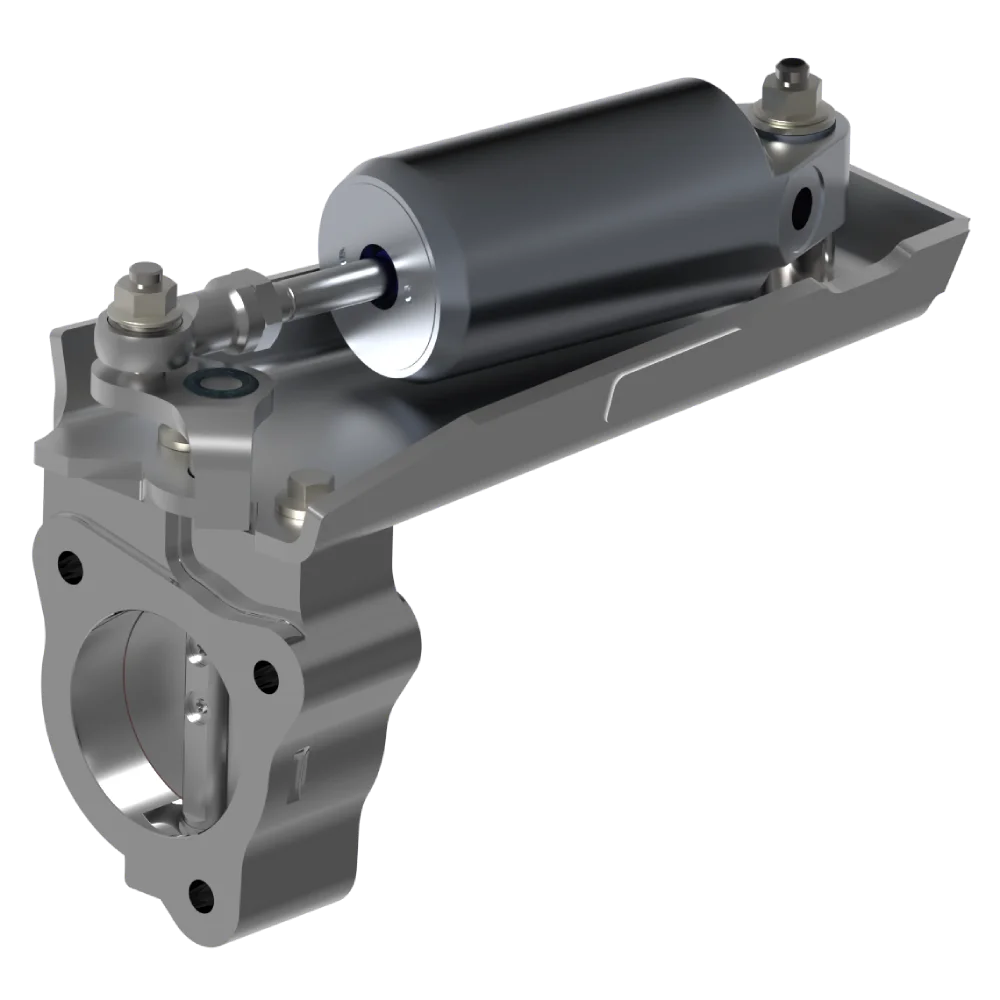

Exhaust Gas Recirculation Valves

Driving efficiency through advanced EGR technology

EGR Valves (Exhaust Gas Recirculation Valves) precisely measure a proportion of the exhaust gas which is then passed through a cooler and recirculated back into the combustion chamber. This reduces the NOX emissions.

GT are proven globally in development and production of EGR valves for a wide range of customer requirements, applications and emissions legislations.

GT continues to develop for the next generation of ICE applications, fuels, emissions legislations and duty cycles.

Engine Size:

4L to 18L

Exhaust Pipe Size:

Ø36mm to Ø60mm (Current Range)

Fuel Types:

Diesel, LNG, CNG, Hydrogen, …

Ambient Temperatures:

Electric: -40°C to +150°C

Pneumatic: -40°C to +250°C

Water Cooling (Electrical), Temperature Shielding

Durability:

Up to 5 million Actuations

Actuator Types:

– Pneumatic with Position Feedback

– Electric (Smart and Non-Smart)

Applications:

On/Off Highway (Includuing: Marine, Constructions, Mining, Agriculture, etc)

Legislation:

Eu3 to Eu7 (And Equivalents) T3 to StgV / PNLT to pPNLT

Our experts are ready to help.