ETV

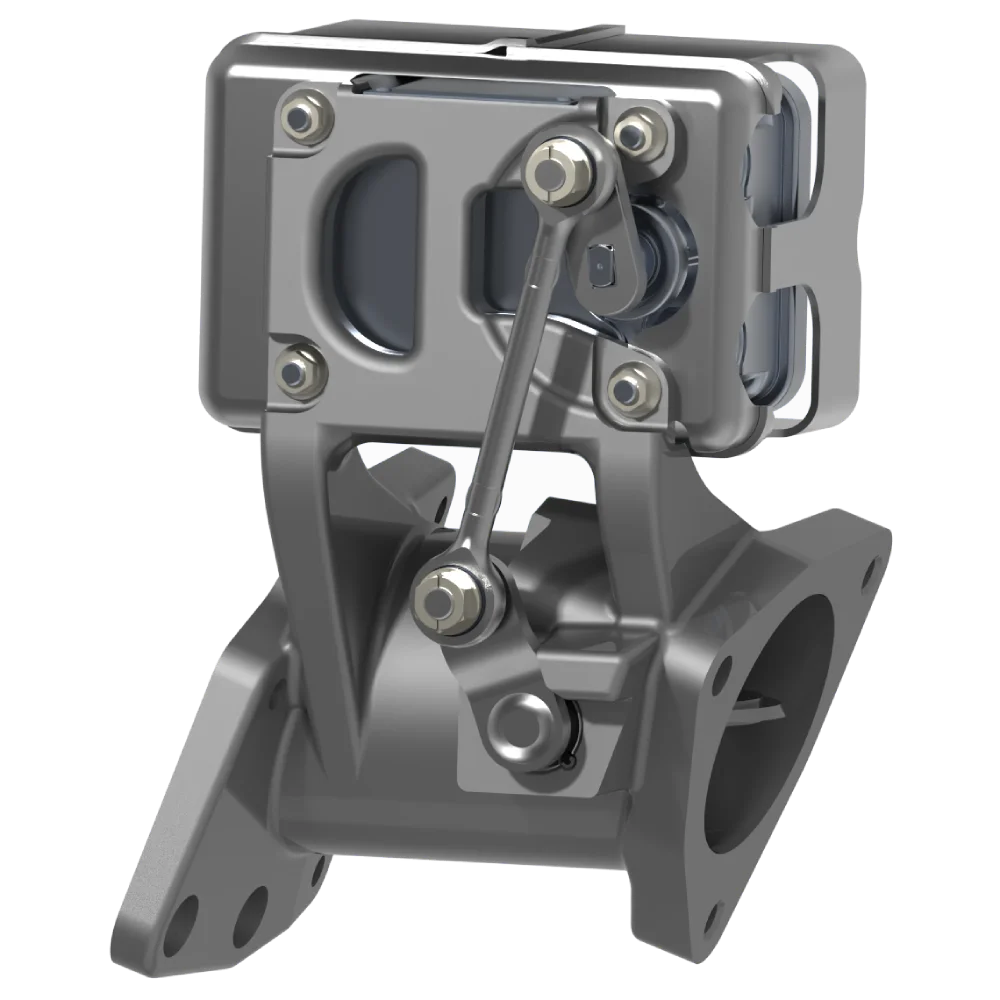

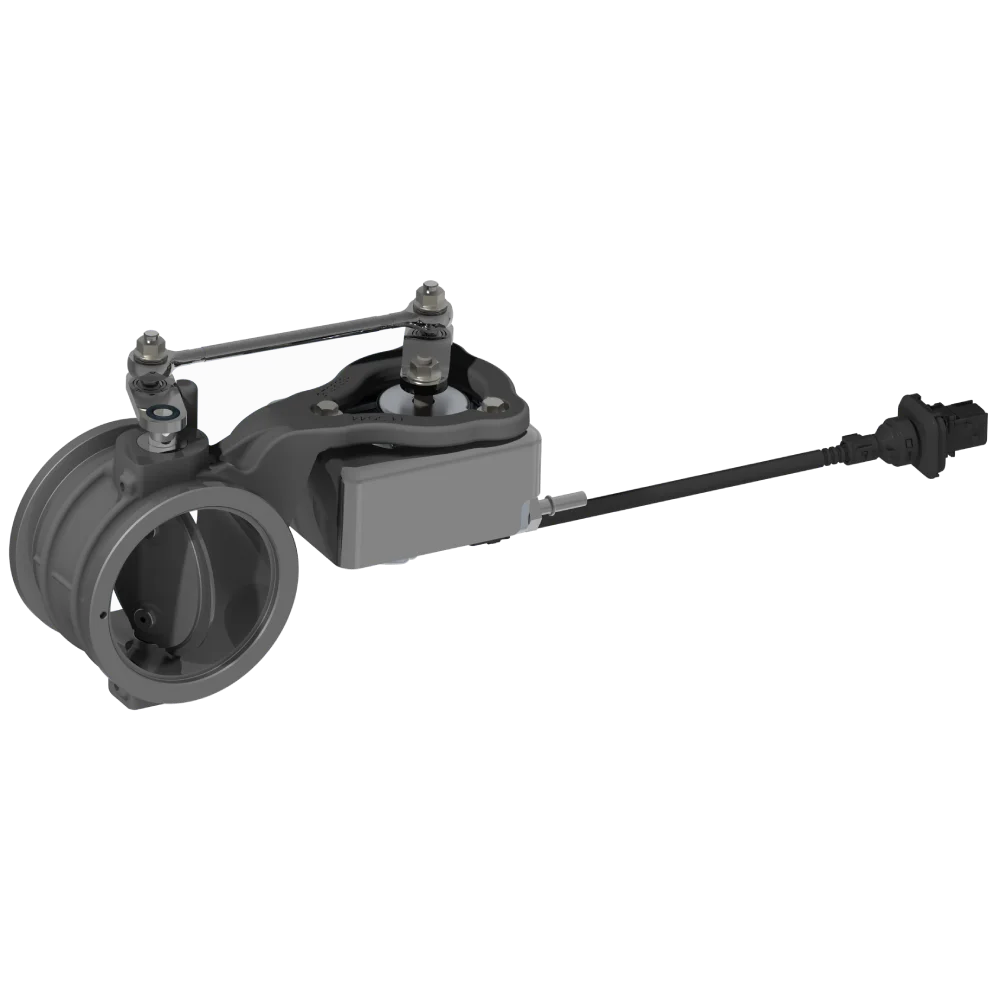

Exhaust Throttle Valves

Optimised airflow control for cleaner, more efficient combustion

An ETV is a component used in combustion engines to regulate the flow of exhaust gases. It plays a key role in emissions control, engine braking, and turbocharger performance.

GT are proven globally in development and production of ETVs spanning a wide range of customer requirements, applications and emissions legislations.

GT continues to develop for the next generation of ICE applications, fuels, emissions legislations and duty cycles.

Engine Size:

4L to 18L

Exhaust Pipe Size:

Ø70mm to Ø120mm (Current Range)

Fuel Types:

Diesel, LNG, CNG, Hydrogen

Ambient Temperatures:

Electric: -40°C to +150°C (Water Cooling / Temperature Shielding)

Pneumatic: -40°C to +250°C

Durability:

Up to 5 million Actuations

Actuator Types:

– Pneumatic with Position Feedback

– Electric (Smart and Non-Smart)

– Hydraulic

Applications:

On/Off Highway (Including: Marine, Constructions, Mining, Agriculture etc)

Legislation:

Eu3 to Eu7 (And Equivalents) T3 to StgV / PNLT to pPNLT

Our experts are ready to help.